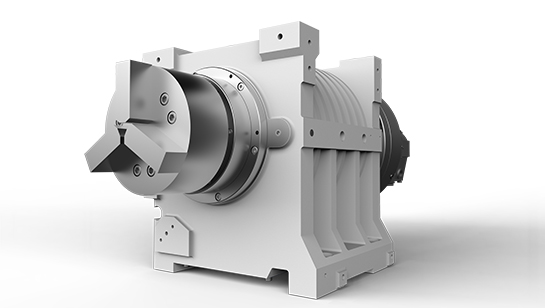

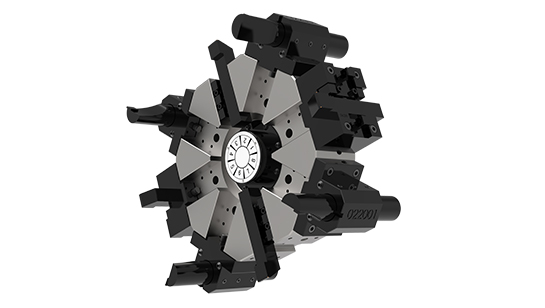

High precision & rigidity mechanical spindle

• The front bearing adopts high precision conical double roller bearing & ball bearing and row angular contact ball bearing,which can bear a greater axial load ,to realize heavy cutting and to replace the grinding.

• Low speed and high torque, high output efficiency

• Spindle driven by built-in motor directly, realize “zero transmission”. Compact design, light weight, low vibration, low thermal deformation. With characteristics of high torque by low speed and high speed. High precision on both dynamic and static, and high stability.

• High precision, high rigidity, high stability, high efficiency.

• Low vibration, low noise, good balance, good thermal characteristics.

English

English