High precision & rigidity mechanical spindle

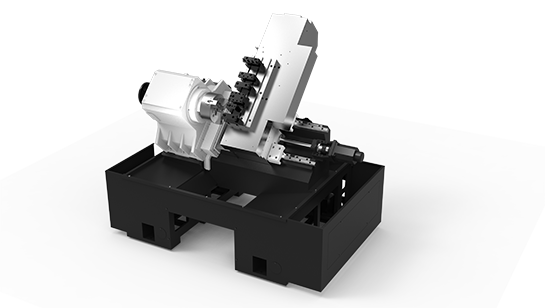

Adopts 45° slant bed, high rigidity and large chip removal space.

Adopts high precision spindle unit( Headman homemade).

High class LM guideway and ballscrew.

Adopts high resolution magnetic induction spindle encoder.

Optionally high rigidity, high power spindle (7.5/11KW, A2-6 spindle).

Higher and more stable machining precision.

Adopts GSK980tb3 or GSK988TA control system.

Reserve automation interface, convenient for automation line set up.

Centralized lubrication system ensures long life span of motion parts.

English

English